Weight calculator metal gets heavy and whether you want to see how much shipping is likely to be or if your vehicle or back can handle it it s good to know what your order weighs.

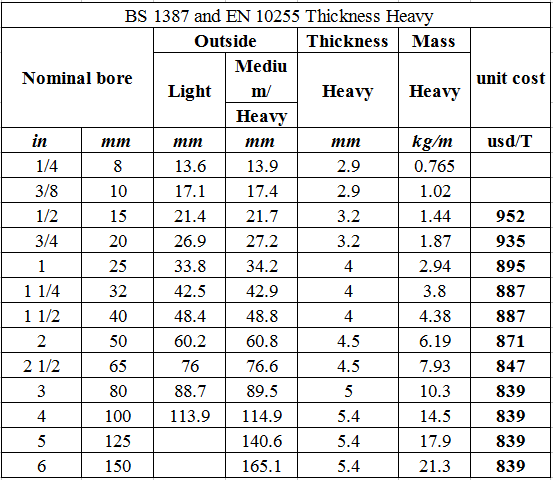

Mild steel round pipe weight chart.

We are leading manufacturers supplier dealers and exporter of ms pipe in india.

Unit steel pipe weight lb per foot is 0 28 x 6 0 28 x 10 69 18 99 lb ft.

S 100 mm size mm section weight kg mtr wt per pc 6mtr no of pcs per mt 35 x 35 x 5 2 60 15 60 64 35 x 35 x 6 3 00 18 00 56 38 x 38 x 3 1 71 10 26 97 40 x 40 x 5 3 00 18 00 56 40 x 40 x 6 3 50 21 00 48.

We stock an extensive range of electric resistance welded erw mild steel pipes tubes in a size range of 1 2 inch n b.

Specification chart of pipes schedules and sizes data for ansi b36 19m and api 5l.

1239 part 1 2004 equivalent to bs.

Mild steel weight chart sizes weights of hot rolled steel long bought to you by.

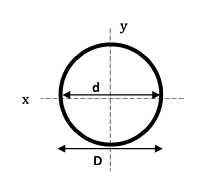

How to get pipe weight from steel pipe weight chart.

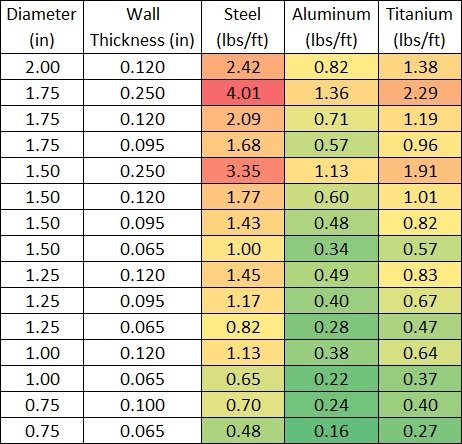

Weights of other materials in pounds per cubic foot simple steel weight formulas note.

Data given in based on the nps tables given by ansi b36 19m and includes pipe wall thickness outside diameter nominal diameter.

To 14 inch n b.

Formulas are based on nominal weights at 2836 lbs.

In the light medium and heavy classes confirming to is.

Steel pipe weight chart schedule 40 and 80 dimensions chart nps outside diameter wall thickness sched weight weight nps outside diameter wall thickness sched weight weight in mm in mm kg mtr lb ft in mm in mm kg mtr lb ft 1 2 0 840 21 0 109 2 769 40 std 1 268 0 851 16 16 000 406 0 188 4 775 47 290 31 748.

After galvanizing the pipes are sent for threading.

To help with that we ve got our handy weight calculator here.

Enter value select units and click on calculate.

We know another to find out pipe weight per foot is through steel pipe dimensions and weight chart this chart is very useful in the pipeline activities.

Earth common loam75 00 90 00 earth dry loose 76 00 earth dry packed 95 00 earth mud packed 115 00 elm white.

Result will be displayed.

The pipes are dipped in a molten zinc bath at a temperature of 450o c to get the proper adherent coating.

After washing the pipe is dipped in the solution of zinc chloride and ammonia chloride to give a base metal for better pickup of zinc on steel surface.